metal shearing machine hazards

In general there are three main types of blow molding. If the porosity is more evenly distributed on the surface of the sample it is called general porosity.

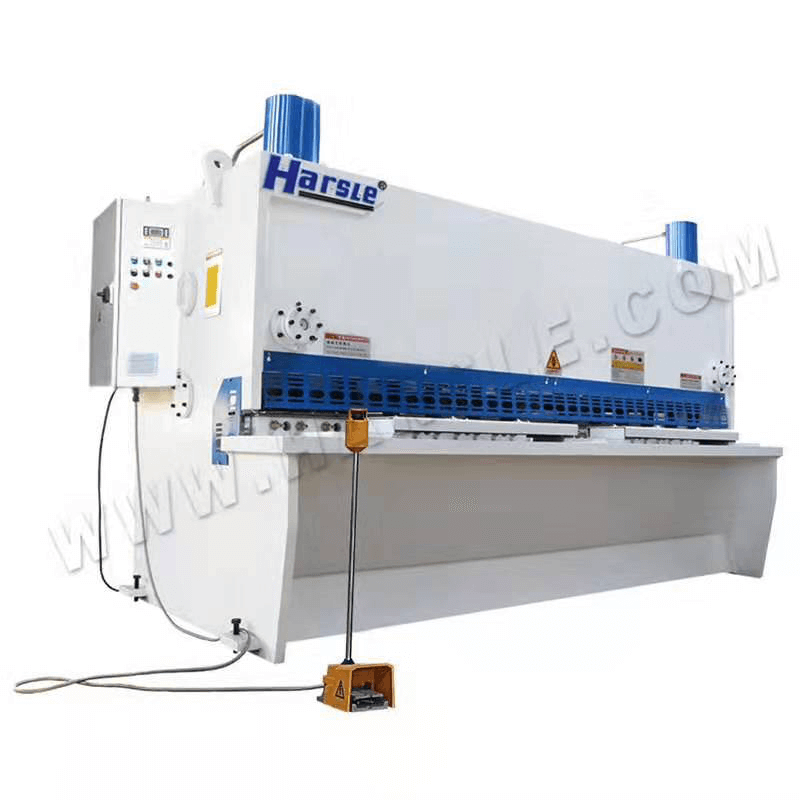

Shearing Machine Skills Training Harsle

InSghear movement of a powered slide or knife during metal trimming or shearing.

. Examples of mechanisms involving cutting hazards include bandsaws circular saws boring and drilling machines turning machines lathes or milling machines. Safety Tips When Fabricating Metal Components Instruments. Both in GBT9943-2008 High-Speed Tool Steel and GBT1299-2014 Tool Steel have clear regulations on the porosity of steel but they often exceed the standard supply.

Known by its comprehensive range of sheet metal machinery AMADA has the solution to suit all your requirements from laser cutting to automation machines. This is to pass some of the gas into a furnace and then through some medium and conditions the gas will explode instantly using the energy produced by the. A hazard involved could include a piece of metal flying out of the equipment while in use.

Parts of the human body can be sheared. C Slitters or slitting machines means a machine ordinarily equipped with circular disc-. The zwickiLine table-top testing machine is equally ideal for research and development as for routine quality assurance testing.

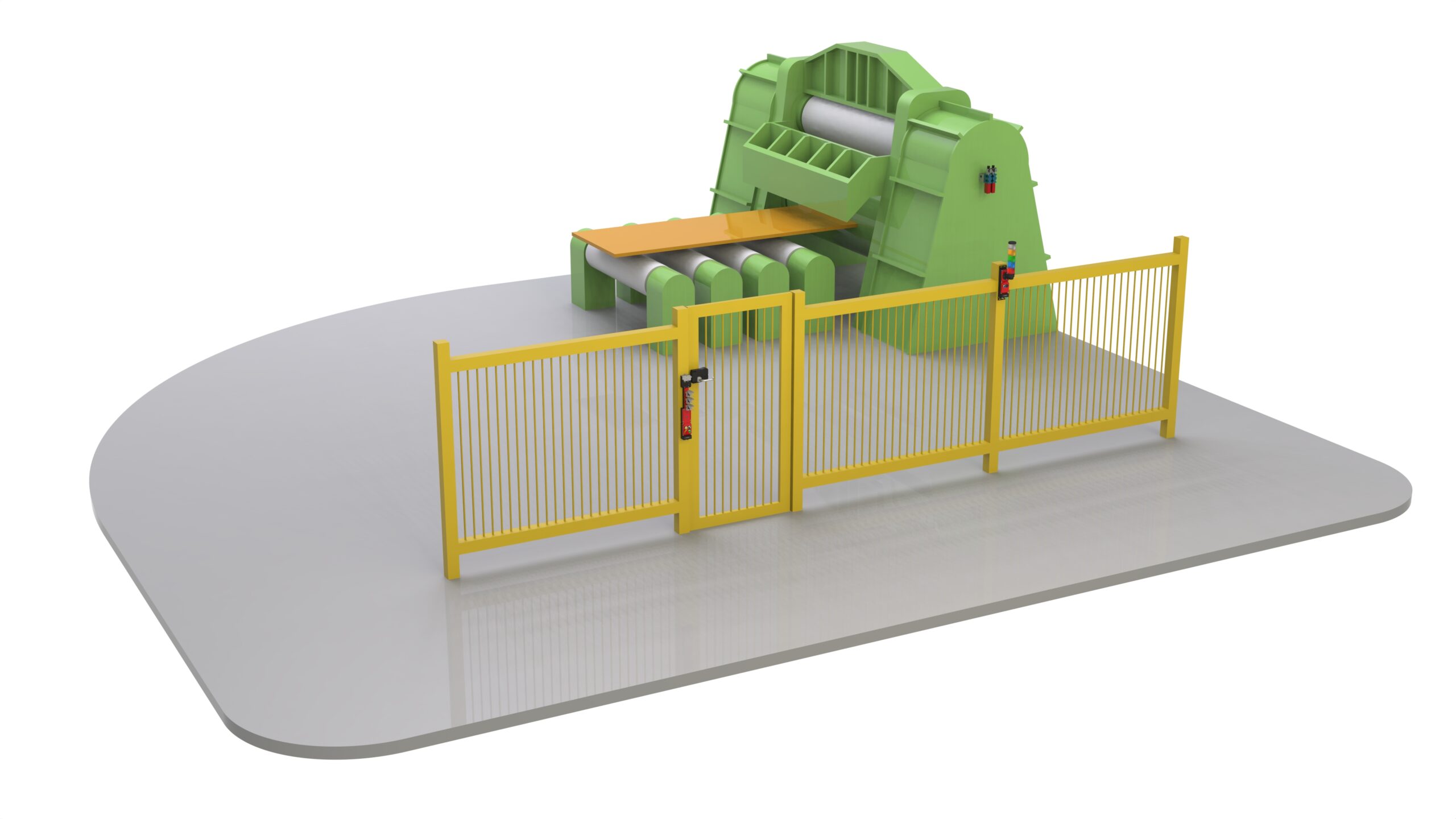

Between two machine parts such as. This guard is itself actuated by the movement of the dangerous part. 512 In the British Standard Code of Practice for Safety of Machinery BS 5304 Chapter 9 describes Interlocking Considerations This standard addresses both guard and braking interlocking and the failure mode needs of interlocks.

The Machine Operator frequently performs quality assurance checks throughout the day inspecting for packaging defects material defects and gum quality Without guidance the Machine Operator troubleshoots machinery breakdowns cleans machine jams and aligns rolls of wrapping materials in an effort to minimize downtimes and promote productivity. Are there any OSHA standards that cover amputation hazards in the workplace. Shear points are found where stock is inserted held and withdrawn.

Suitable for aluminum alloy die castings with small burr wall thickness and small volume. Such hazards are present at the point of operation in cutting wood metal and other materials. The method is also called the thermal deburring or explosion deburring.

Deburring by thermal explosion. Moving machine parts create workplace hazards and potential machinery-related injuries making machine guards vitally important. AMADA is a worldwide leading manufacturer of sheet metal machinery.

Control of Industrial Major Accident Hazards Rules CIMAH Rules 61-UA. Moves a slide ram to stamp or blank metal or other material. Provide a valid e-mail address.

Material that is substantial enough to withstand impact and prolonged use are all used as construction materials for machine guards. Automatic guards will ensure that the operator is prevented from coming into contact with dangerous parts when the machine is set in motion accidentally. All e-mails from the system will be sent to this address.

Follow the manufacturers instructions for operating the machinery safely. 149 6 through 6F. 453 CMR 600 shall establish andor constitute.

Electrical control interlocks are common where rapid or frequent access is required into a machine. The e-mail address is not made public and will only be used if you wish to receive a new password or wish to receive certain news or notifications by e-mail. 453 CMR 600 is promulgated in accordance with and under the authority of MGL.

Blow molding or moulding is a manufacturing process for forming hollow plastic parts. It can only be used where sufficient time is available to remove the body part from the danger zone viz. Mining is the extraction of valuable minerals or other geological materials from the Earth usually from an ore body lode vein seam reef or placer depositThe exploitation of these deposits for raw material is based on the economic viability of investing in the equipment labor and energy required to extract refine and transport the materials found at the mine to manufacturers who.

A Requirements necessary to protect the health and safety of the general public and persons engaged in or associated with the removal enclosure encapsulation or disturbance of. Figures 12 and 13 show some ways operators can be injured by shearing hazards. B shears or shearing machine means a machine ordinarily equipped with straight level-edged blades operating vertically against resisting edges or with rotary over tapping cutting wheels and used for shearing metals or non-metallic substances.

Bending action occurring when power is applied to a slide to draw or form metal or other materials. Porosity has a great impact on the strength of steel the main hazards are as follows. Shears or Shearing machine means a machine ordinarily equipped with straight bevel-edged blade operating vertically against reasisting edges.

Power press means a machine used in metal other industries for moulding. In many circumstances metal is the best material. Shearing trims or shears metal or other material with a powered knife or slide.

Be aware of your surroundings and stay clear of moving parts. Extrusion blow molding injection blow molding and. To illustrate how this can be used in the workplace we will use the example of a metal shearing task.

It is also used for forming glass bottles or other hollow shapes. Development and manufacture of zwickiLine including all mechanical electronic and software componentstogether with the comprehensive range of accessoriestake place at ZwickRoells production facility in Germany so all components. 348 Shearing hazards.

Wear appropriate Personal Protective Equipment PPE such as gloves safety glasses and ear protection. This is a very important step in any metal fabrication projectA detailed training session regarding the equipment occupational hazards and working conditions should be given to the personnel. In this example the probable most severe injury would be Major or Serious Injury with the possibility of bruising breakage finger amputation.

There are several ways to protect yourself from these hazards. Shearing action involves applying power to a slide or knife in order to trim or shear. The following steps can be employed when using metal fabrication tools.

Engineering Research Express ERX is a broad multidisciplinary journal devoted to publishing new experimental and theoretical research covering topics extending across all areas of engineering science including interdisciplinary fields.

The Precaution Of Sheet Metal Shearing Machine Blma

Shearing Machine Skills Training Harsle

6 Important Shearing Machine Safety Precautions

Vertical Grain Feed Processing Mixer In 2022 Poultry Feed Grinding Machine Poultry

Safety And Maintenance Of The Guillotine Shear Machinemfg

Cutting Corners On Machine Safety A Common Problem Graphic Products

The Precaution Of Sheet Metal Shearing Machine Blma

Pin On Cnc Plate Shearing Machine

Sheet Metal Guillotine Shear Safe Operation Shenchong

Safety Precautions Tips To Follow When Working With Sheet Metal Rolling Equipment Woodward Fab Blog

Safe Operation Regulations And Maintenance Of Hydraulic Shearing Machine Harsle Machine

High Uniformity Stable Cnc Steel With Hacmpress High Uniformity Steel Sheet Bending Machine Wc67k 100 2500 Image Of High Uniformity Automatisierung Cnc Bend